What is a Clean Room?

The clean room a specially-engineered held room at an excessively lower quantity of toxins such as dust, airborne microbes, and other unwelcome particles. Clean spaces is beautifully made with the good reason of protecting products, processes, and workers from contaminants which may result in failure or damage.

Advantages of a Clean Room

Clean rooms are essential in industries the place where a nearly qualification all of is necessary, such as pharmaceuticals, biotechnology, nanotechnology, and microelectronics. The advantages for the numerous clean rooms, like:

1. Increased safety: Clean rooms protect workers from dangerous materials, for instance bacterium, malware, and toxins. Additionally, they lessen the possibility of contamination from outside elements.

2. Improved quality: Clean spaces promise that the ultimate item is of high quality and satisfies the mandatory standards.

3. Greater innovation: Clean rooms offer a breeding ground where analysis and development could be executed with a higher diploma of and precision.

4. Increased productivity: By minimizing the possibility of contamination, clean spaces enhance production efficiency and throughput.

5. Compliance with regulations: a clean room clean that products are stated in compliance with regulatory requirements.

Requirements of a Clean Room

The clean room meet specific requirements put by industry requirements. These needs are essential to help keep a controlled environment minimizes the introduction of toxins. What's needed associated with the available clean room:

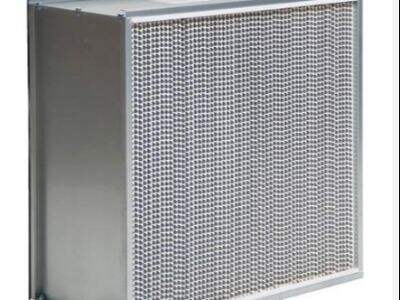

1. Clean air: Clean spaces require free atmosphere of dust, particles, and more pollutants. The atmosphere must be recirculated through the use of high-efficiency particulate air (HEPA) filters by Huirui.

2. Positive pressure: The clean room should be maintained at a confident pressure according to their environments to prevent the entry of contaminants.

3. Regular cleansing: The clean room be washed regularly to remove any particles which may have settled on areas.

4. Protective clothing: Personnel active in the clean room put protective clothes to cease the introduction of contaminants from outside.

5. Controlled heat and moisture: The heat and moisture when you look at the available clean room be controlled to end the introduction of microorganisms.

How to Use a Clean Room?

Using the clean room a strict protocol to be sure that environmental surroundings stay sterile and free of contaminants. The protocol is the after steps:

1. Entry: Personnel should submit the available clean room an airlock or the gowning area to attenuate the introduction of contaminants.

2. Gowning: Personnel should wear protective garments like a gown, gloves, mask, and hair net.

3. Pre-cleaning: before beginning any ongoing work, workers should clean the workshop and equipment.

4. Work: all ongoing work should be carried down within the designated area to avoid the spread of contaminants.

5. Post-cleaning: After completing the ongoing perform workers should clean the area and equipment completely.

Service Quality for the Clean Room

The clean room an investment that needs proper repair service to make certain that it remains practical and effective. The service quality regarding the clean room essential to make sure it meets the necessary standards. The after is included by the service quality:

1. Regular repair: the available clean room to be maintained regularly to make certain all equipment is functioning precisely.

2. Calibration: All equipment like hepa air filtration must become calibrated regularly to ensure that it is accurate and dependable.

3. Record-keeping: all ongoing service must become recorded to make certain they are executed correctly.

4. Training: All workers involved using the clean room learn its use and repair.

Application for the Clean Room

Clean spaces has a true wide number of applications in diverse industries. The application for the available clean room:

1. Pharmaceutical industry: within the pharmaceutical industry, clean spaces are acclimatized to make certain the manufacturing of medicines is sterile and contamination-free.

2. Biotechnology industry: Clean rooms is placed into the biotechnology industry to uphold sterile conditions for studies and developing.

3. Nanotechnology industry: clean room are located into the nanotechnology industry to prevent the contamination of delicate electronic equipment.

4. Microelectronics industry: Clean spaces are used into the microelectronics industry to stop the contamination of microchips and more electronic elements.

EN

EN