Sandwich panels provide great support in clean rooms. Clean rooms are unique areas of a facility that must stay clean and safe. Sandwich panels prevent the entrance of dust or dirt into these rooms. Here in this Write Up we will learn in some depth about Sandwich Panels, continue to discuss the advantages of So onto Sandwich Panels then move on to the methods of their correct Installation such they function efficiently.

What Are Sandwich Panels?

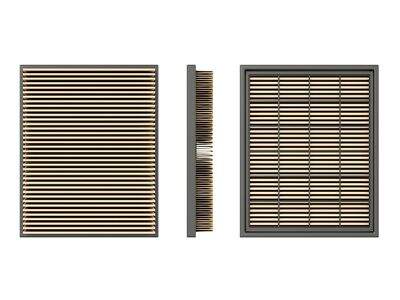

The sandwich panel consists of three main parts: two outer layers called face sheets and a middle part known as the core. The outer layers can be fashioned from aluminum, steel or fiberglass. These aluminium sandwich sheet materials are powerful, protecting the insides of the panels. The core which is the variable part is mostly foam or honeycomb. These materials are good insulators, so they help stabilize a clean room temperature.

In a clean room, sandwich panels are good because they are like a wall. They keep dust, dirt, and other particles from coming indoors. This ensures that the clean room remains clean from any contamination and other issues that could be problematic. It is of utmost importance to keep the room clean in order to keep the people and products inside safe.

What is the Purpose of Sandwich Panels?

Sandwich boards help in numerous approaches:

Keep the Room Clean: Their primary purpose is to prevent dust and dirt from entering. In a clean room even the smallest particles can be problematic so this is extremely crucial.

Excellent Insulation: They retain the room temperature. This ensures the room is maintained below the upper threshold or higher than the lower threshold for the perfect temperature level that is required for all people along with the equipment not getting heated up or cooled off too much.

Soundproofing: Sandwich panels can also help to keep the room more silent. This is crucial in areas where we need individuals to concentrate and focus.

Luminous Efficiency: The nature of OLEDs allows to use them to make walls, ceilings and even floors. This proves highly beneficial in the construction of clean rooms that fulfill the meticulous requirements.

SCENARIO SETUP: Design a clean room with sandwich panels

Here are some considerations during planning for a clean room with sandwich panels:

Room Size: On the first place, think about the size of the room. You have to measure the room and see how many panels you will require to get full coverage of the area. This is useful to make sure it all fits nicely.

What type of panels: Now you need to consider what kind of aluminium sandwich panel you are going to use. The paper also looked at the materials and insulation properties of the panels, which can vary based on the requirements of individual projects.

Making sure to get the thickness of the panels right: You will also have to decide how thick you want all the panels to be. With thicker panels, the insulation and protection could be better.

Yes, the second thing you should consider is how the room will be arranged. Install the panels, so that the flow and access to the room stays functional. Ensure that you don't have any cracks or holes where dust & debris will enter the room.

How to Install Sandwich Panels Properly?

There are certain practices to be observed during the installation of sandwich panels in clean rooms:

Engage Professionals: It is crucial for this to be done by professionals who are well trained in panel installation. So these are the pros that know how to get the job done right and they make sure that the panels are installed properly. This will ensure that the clean room operates as intended.

Use the Right Tools: Do not use ordinary tools; instead, use tools specifically designed for the installation of sandwich panels. For example, drills, screws and other equipment. The right tools will ensure the installation process goes as smoothly as possible.

Ensuring That the Clean Room Is Effective

In order to ensure your clean space is the very best you can make it, high quality sandwiches and the correct steps to make sure you are putting them in the clean room must be done. This assures that the panels would work well and properly. Quality materials will ultimately last longer and perform better in the clean room environment.

Follow Clean Room Standards

Clean rooms had and still have, many rules and regulations which need to be followed. The ISO 14644-1 standard specifies the criteria for clean room design and construction, for example. These standards should be followed in order to ensure that the clean room is compliant with safety and operating specifications. In addition to this, materials are needed which have been manufactured to these standards and which are critical for the production of a reliable clean room.

Conclusion

In short, alu sandwich panel play a critical role in the design and operation of clean rooms. They have lots of advantages, such as noise reduction, main-tain temperature and blocking out harmful particles. There are important considerations and best practices to keep in mind for sandwich panel design and installations. Following this step, you can keep your clean room safe, functioning and effective. Huirui stands ready to assist with all your clean room design and installation needs, so that your space is up to snuff.

EN

EN